How do you create a new boilie for carp fishing?

Between myths and realities, we truly explain how a new boilie is born. From conception to sale, including testing, this article explains everything to you.

Table of content

1. Introduction

2. Boilie: From Idea to Concept

2.1 Regulation: Ingredients and production must comply

2.2 Mechanics: The Boilie Must Be Perfectly « Rollable »

2.3 Balance: A Key Element of a Boilie

2.4 Signature Ingredients

2.5 Fast-Acting Ingredients: Liquids

3. From Prototype to Market Introduction

3.1 Behavior and Durability of the Boilie

3.2 Acceptance and Instant Attraction Testing

3.3 Tests with Pre-Baiting and Short Sessions

3.4 Tests with Larger Pre-Baiting and Longer Sessions

4. Conclusion

1. Introduction

We are not aware of the methods used by others to create new baits, but we are able to explain the genesis of our range. Since the advent of boilies, this bait has sometimes sparked surprising creativity and imagination. The possibilities of recipes to create an effective boilie are limitless.

That's why we designed our baits based on a fundamental idea that is present in all our boilies: insects. We relied on scientific observations demonstrating that the carp's diet is carnivorous, with an omnivorous tendency. Insects are an integral part of its diet, just like many other fish. It is from this realization and our extensive experience as carp anglers that our range was built. Thus, our boilies came to life thanks to an original idea, a "signature" ingredient.

2. From Idea to Concept

Our initial concept is to create a range of boilies centered around insects. The first step in our research and development is to determine which types of insects we want to incorporate and in what forms. It's not just a matter of choosing any insect and adding it to a basic recipe. We must first find an approved flour for use in animal feed to comply with regulations.

Additionally, we must keep in mind that the boilie must be perfectly rolled, its preservation must be controlled, it must release attractants into the water while maintaining its durability, and, of course, it must be appealing to carp. It's a comprehensive program ahead of us.

2.1 Regulation: Ingredients and production must comply

In recent years, baits used for carp fishing have been subject to stringent regulations, as they are now considered animal feed. With this in mind, from the outset, we chose to focus on bait design and entrusted the production to specialists.

We believe that the added value lies more in the design than in production, as the latter requires specific skills. By outsourcing the production process, we have also expanded our network of experts, allowing us to achieve even more refined work. Therefore, from the beginning, we decided to involve our future suppliers in the development of our range. We presented them with our initial concept and ideas to explore various formulation possibilities together.

Our initial ingredient selections were made in compliance with current regulations, and only approved ingredients were therefore retained.

2.2 Mechanics: The Boilie Must Be Perfectly « Rollable »

This aspect of production is of crucial importance. Before being used, a boilie must be produced following precise specifications. At this fundamental stage, our collaboration with our future suppliers proved to be a key element that enhanced our efficiency.

These highly specialized manufacturers have a deep understanding of the mechanics of various ingredients that can be used in bait composition. Although they had never used insect components before, their expertise allowed us to quickly identify what was feasible and what was not. We conducted the very first tests with the selected ingredients, using significant proportions, to determine if our insect-based boilies could be mechanically rolled.

These initial tests validated the concept in terms of pure production. We were able to define the types of flours and the maximum proportions until the bait became unworkable within the manufacturing process.

2.3 Balance: A Key Element of a Boilie

The concept of balance has several dimensions here. The first involves ensuring that the entire recipe can be rolled, as we explained earlier. Once the upper and lower limits of the different ingredients have been defined, we work on a much more complex balance to achieve, but one that will give the boilie its full potential, the boilie nutritional equilibrium. It is at this stage that the role of the bait designer truly comes into play.

We rely on the N.A.D concept, which encompasses Nutrition, Attraction, and Diffusion. A good boilie is one that manages to find the right balance between these three factors.

2.4 Signature Ingredients

All the boilies in our range feature insects as signature ingredients, in various forms. To differentiate our baits within our range and offer boilies suited to various types of fishing, we incorporate signature ingredients. For example, liver powder, predigested fishmeal, tiger nut flour, spices, marine extracts, yeast, and more. These markers give a distinct identity to the bait, enhancing its attractiveness and allowing carp anglers to adapt to the season, fish behavior, water characteristics, while improving certain mechanical aspects.

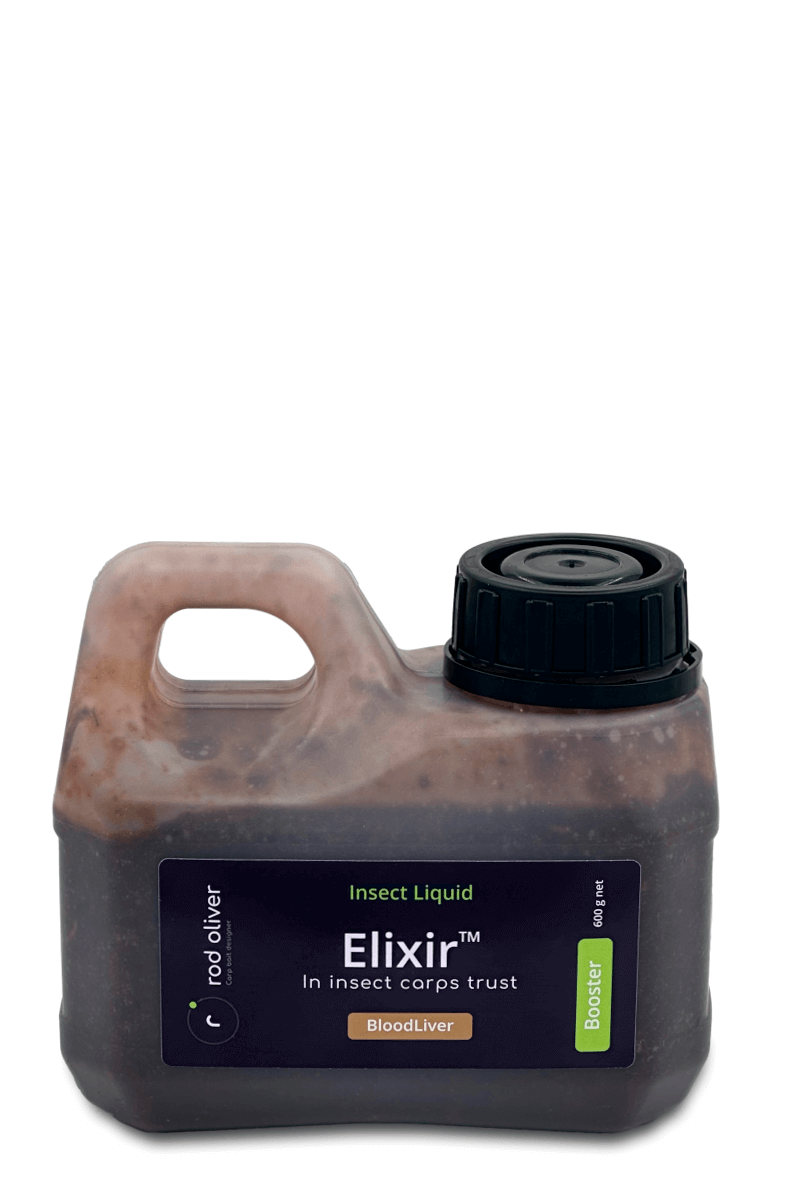

2.5 Fast-Acting Ingredients: Liquids

There is no limit to the incorporation of natural liquids into boilie recipes. The only restriction is to ensure that they do not make the boilies impossible to roll. In many cases, a limited quantity is more than sufficient because these products are pure and concentrated.

Our boilies are generously infused with these liquids, not only to enhance their nutritional profile but primarily to promote their diffusion. These completely soluble products act instantly as soon as they are immersed in water.

3. From Prototype to Market Introduction

After the research and development phase, the first prototypes are finally put into the water, marking an important and eagerly awaited moment. This is the beginning of testing. At each step, our boilies undergo intensive testing. The testing process, often surrounded by myths, is actually a rather laborious step that requires us to fish not according to our preferences but following precise specifications. However, it is essential to ensure a refined bait that is effective and meets our expectations.

3.1 Behavior and Durability of the Boilie

During our initial tests, we focus on the behavior of the boilies once they are mounted on the hook hair. Tests are conducted in various conditions, fishing in different waters. Rods are raised at different times to observe the behavior of the boilies, their durability, and their dissolution level over hours.

The tests are conducted at various water temperatures and on different types of bottoms, ranging from currents to simple ponds.

We extend the tests for many hours, sometimes even more than 24 hours of immersion. At each check, we carefully analyze the boilie: its color, shape, level of dissolution, odor, and so on.

The primary goal of these initial tests is to evaluate the durability and diffusion of the boilie, allowing us to measure the immediate impact of the bait. If adjustments to the structure are necessary, such as the addition or removal of hardening ingredients, we make note of it.

The essential goal is to find the right balance between diffusion and durability.

3.2 Acceptance and Instant Attraction Testing

Once durability tests are completed, we move on to the phase of attraction and effectiveness testing, which is both the most anticipated and the most complex from a technical perspective, due to the multitude of parameters to consider.

The tests are exclusively conducted with the boilie to avoid biasing the results. Fishing is mainly done in locations we are familiar with, allowing us to compare them to previous fishing sessions and control the positioning of the right fishing spots.

The initial goal is to assess the bait's acceptance capacity, meaning analyzing the boilie's immediate effect without prior baiting. To do this, we fish in as many different waters as possible, including ponds, gravel pits, canals, reservoirs, and so on. The objective is to determine if the boilie can attract fish in all these types of water bodies and to identify any notable differences between different types of fishing locations.

These tests also allow us to observe the boilie's behavior during quick fishing sessions, ranging from a few hours to up to 48 hours, without prior baiting. Baiting is done with soluble pva and limited quantities, typically around 100 to 150 grams per rod, with occasional re-baiting between bites.

3.3 Tests with Pre-Baiting and Short Sessions

In this testing phase, we focus on the behavior of the boilie using limited pre-baiting quantities. For all sessions in this phase, we perform a simple pre-baiting the day before fishing, using quantities that vary depending on the location but are always relatively small, typically between 1 and 3 kilograms of boilies in the fishing area.

Fishing sessions also range from a few hours to a maximum of 48 hours, with re-baiting between bites. The goal is to evaluate the effectiveness of a small conditioning pre-baiting in order to measure the immediate impact of the boilie.

3.4 Tests with Larger Pre-Baiting and Longer Sessions

In this scenario, our objective is to observe the carp's response to a larger pre-baiting and over a longer period, with a week-long fishing session in the same spots.

In this case, having a high-quality bait that is both nutritious and doesn't satiate the fish's appetite is essential. Nutritional balance and bait profile play a crucial role. If we observe a decrease in bites despite apparent carp activity, we have two possibilities: either the boilies are not attractive enough in the long term and require improvement in their nutritional profile, or they are too rich, for example, in fats, and adjustments are needed to reduce the fat content of the bait.

A situation where fish continuously feed would confirm the nutritional profile of the boilie. It's evident that these tests are quite complex to conduct because it's important to maintain similar weather conditions and not bias the study.

4. Conclusion

All the tests mentioned above are conducted in different types of waters and seasons to obtain reliable conclusions. Once all the tests are completed, we exchange our findings with our suppliers to make the final necessary adjustments to arrive at the ultimate recipe. In this case, a small batch of tests is then carried out to confirm the slightest changes made, and finally, the boilie is launched on the market.

It's important to understand that between the initial idea on a blank sheet and the commercialization of the final boilie, it will take approximately two years. This research and development period is costly, both in terms of time and financial resources. The final cost of the boilie is not limited to the sum of ingredient, manufacturing, and packaging costs but also includes investments in research and development as well as testing phases.

In the event of negative test results, either the boilie is simply abandoned, or it undergoes a major redesign. In such a case, we would start a new comprehensive testing phase. Even once commercialized, a boilie is never truly finished in its development. Customer feedback is a source of continuous improvement, and the recipe can be modified over time, taking into account all the feedback received. Our goal is to have a continually more effective product.

That's why we always pay close attention to well-reasoned feedback from our customers.

Tight lines !

rod oliver